Smart Stickers

Decreasing shipment handling time

About Bosta

Bosta is a leading logistics company operating in Egypt and Saudi Arabia. Bosta provides a mobile app and dashboard for sellers to create shipping orders, Bosta couriers then pick the order up from the seller and deliver it to the customer.

The problem

In order to send shipment you’ve to print a paper that has all shipment details, which requires a printer.

That paper is called AWB, and it’s crucial for our couriers and warehouse people to direct the shipment to the correct address.

According to our numbers, we serve many sellers who ship 1-20 orders per month and won’t invest in buying a printer. Usually, they go to the nearest print shop every time they get 1 or 2 orders which is a hassle.

The Goal

Our goal for this project was to help small businesses ship easier with Bosta without having to buy printers to meet our delivery requirements while maintaining our operations workflows in the warehouses.

- Make it really easy for a starter seller to deliver without hassle.

- Save time and money for the sellers.

- Maintain the operations workflow to avoid increasing efforts or costs.

My role

I led the research and design experience of the operations workflows while my design teammate focused on seller experience. Team: Mohamed El-Araby, Nada Ibrahim.

Current seller’s experience

To better understand the problem, let me first introduce you to our current seller’s experience to ship an order with Bosta:

- Buy packaging materials.

- Prepare your order and print the AWB.

- Create the order on the system.

- Hand the shipment to the courier.

Introducing Smart Stickers

The initial solution

In order to replace the need for printers we initially proposed a solution of providing stickers that have barcodes on them, which will ease the experience in this way:

- Buy stickers from our online shop.

- Prepare the order and put the sticker on.

- Use our app to link between the physical sticker and the order on the system.

- Hand the shipment to the courier.

The solution was a nightmare for our operations team.

The operations hassle

For the seller, it’s the experience they dream of, but for the people at our warehouses, this solution comes with a real hassle and big changes in the flow.

To better understand how this affects our operations we conducted user research with the teams in our main hubs. Multiple visits were arranged for a detailed field study with the goal of discovering how they work in detail:

- What are their roles and exact workflows?

- How do they handle shipments?

- How much do they rely on the AWB?

- What are their workarounds?

Insights

After arranging multiple visits and talking with employees and managers at warehouses, we’ve come up with some insights to move forward.

We found that the current workflow of the warehouse starts with an employee who receives shipments from pickup couriers, then another person sorts them to cities, and the last person sorts them again to specific zones.

The AWB played a crucial role in our observations. The one who receives the shipment scans the barcode on the AWB (which is okay to replace with the sticker), while all the sorting work is based on the address that is written on the AWB which means no sorting can be done without AWBs.

Therefore, we discovered that we need to inject a step after receiving the shipment to print the AWB and stick it to continue the sorting process as-is.

The handling time is very critical

From our findings, we knew that adding any new steps would increase the efforts and handling time of shipments.

Knowing that receiving a shipment takes around 3 seconds, city sorting takes 5 seconds, and zone sorting takes around 8 seconds. That makes an average of 16 seconds to handle one shipment. Let’s do the math, to handle 1000 shipments it takes around 4.4 hours, and if we assumed printing AWB for the shipment will take additional 20 seconds, that means 10 hours for the same 1000 shipments, that’s a whole 127% increase!

Injecting the printing step

The challenge here was thinking of a way to handle the printing of each shipment extremely fast without adding much extra time that would ruin the entire flow.

I proposed the solution of adding a printing step right after receiving shipments. Each received shipment will be sorted into shipments with AWBs and others with stickers. The ones with AWBs will continue the process as-is, while the sticker shipments will take the printing route.

An extremely fast printing method was needed

After aggregating shipments with stickers, the employee then starts to handle each shipment on its own by using the new page I designed specifically for printing AWBs.

The employee has to pick a shipment, scan the sticker with a barcode gun, print the AWB, take it out of the printer, and stick it on the shipment.

I made sure to keep the handling time to the minimum by forcing the system to auto-show the printing modal right after scanning a sticker which made the experience much faster.

Instead of scanning then clicking print and confirming the request, now once you scan, it will show the request and then you can just click Enter and that’s it

Testing how fast and reliable it is

I planned a real-experience usability test with hub employees in their work environment. A total of 100 fake orders have been created on the staging environment and physically prepared with stickers used in different places on the shipment. I made sure to make it as realistic as possible.

The employee was asked to handle each 20 shipments in a different way:

- Handle 25 shipments with normal scanner.

- Handle 25 shipments with auto scanner.

- Handle 25 shipments with a teammate.

Testing results

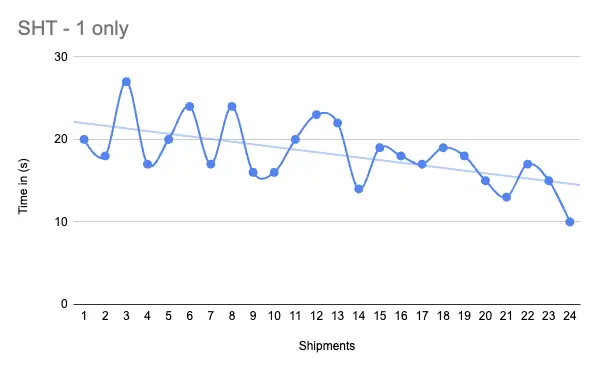

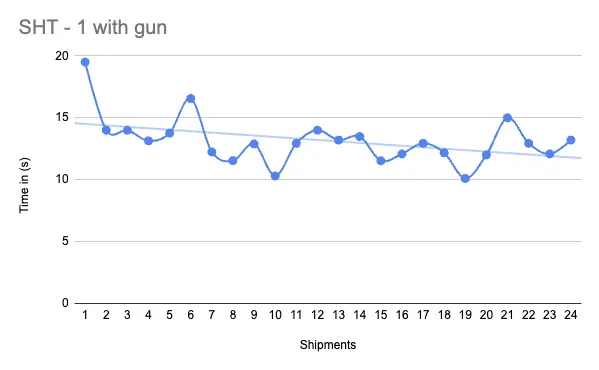

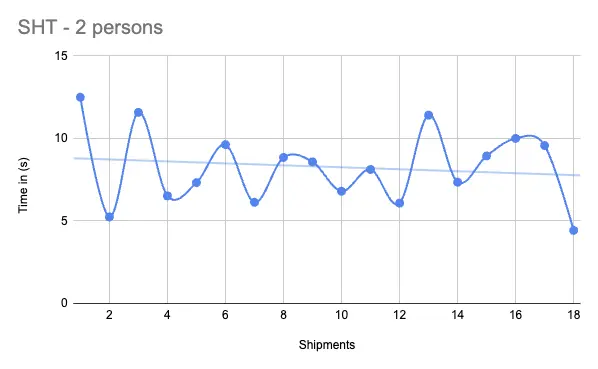

One of the main key findings from the test is it gets much easier with practice, as can be seen in the below graphs the trend line is always going down.

After trying out different methods we can obviously see that two people working on handling the same shipment is much faster, but due to our workforce limitations, we’d go with the one-person solution.

A person can handle 1 shipment in 18.30 seconds.

A person with an auto-scan barcode gun can handle 1 shipment in 13 seconds.

Two persons can handle 1 shipment in 8.30 seconds.

Decreasing handling time by 30%

As per our observations and testing results, we came to the conclusion that providing auto-scan standalone barcode devices instead of normal guns will drop the handling time by 30%.

The impact

This feature went viral within our customer base, as more than 1,300 merchants purchased the stickers, and shipped more than 20,000 without a single printer!